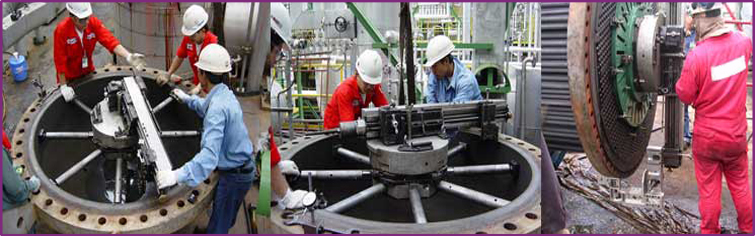

Flange facing is a process of machining the faces of flanged and other types of pipe and vessel connectors. It is used to repair faces either damaged from impacts with other components during construction or installation or from corrosion and erosion due to turbulent flow or cuts from casket leaks. Also included in the process of flange facing is the machining of hub profiles, the front and rear faces of heat exchangers, oval manways, oval handholds and sealing surfaces of pressure vessels and boilers is possible.

Flanges and connectors can be re-machined to original specifications conforming to relevant standards such as:

- BS

- ANSI

- API

Machinable flanges are:

- Full face

- Raised face

- Ring groove

- Techlok/Grayloc type clamped connections

- Flange plus connections

- Blind

- Lens rings

- Tube bundles sheet face and back faces

- Square, oval and irregular shaped manway doors

In addition, flange facers can be used to generate weld preps, with O/D mounted machines used for boring, using appropriate accessories. Grinding and polishing attachments are also available.